Rentals

One of the largest management items for companies in the oil and gas sector, is that of Rentals.

These are items mobilised offshore for a period of time with the costs being set on a daily/ monthly rate. The management of when these become mobilised, their date for mobilisation and subsequent tracking of the dates, can be a draw on resources and require spreadsheets to manage. SAP provides Rental functionality within the Remote Logistics Module and Absoft has the experience and additional knowledge and tools to help manage these.

To help manage Rentals more efficiently, they can be split into the ‘physical item/ equipment’ which needs to be receipted, shipped, utilised and returned to vendor and that of the costs per day/ month which need to be approved and invoiced. RLM Rental functionality allows for the user to enter the requirements for a rental then utilise additional fields to identify it as a rental item to be mobilised, packed and shipped etc.

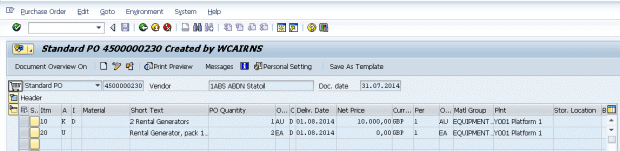

The subsequent purchasing documents shows the additional fields, but the process for approving the requisition and creating the purchase order are as standard.

However, when the purchase order is created and saved, the rental item is now split into that of a GR based item and an item requiring a service entry or invoice.

From this, item 10 is managed as requiring the Service Entry (Receipt) then Invoice, while item 20 is used for shipping and transportation purposes.

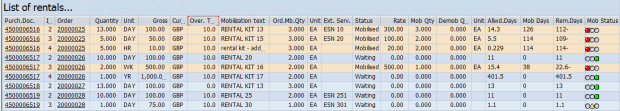

The additional mobilisation status flag, gives information on where the rental item currently sits within the supply chain process i.e. waiting, mobilised, demobilised. This can be used for reporting but also for determining when the item is available to be used in the Returns process.

Standard SAP RLM provides some limited reporting and tracking for rentals items, but Absoft has been working with SAP and major oil and gas operators, to help make improvements in the area of rental reporting and has developed an in-house solution for the purposes of aiding invoice matching –

Rental equipment can therefore be easily identified and processed within SAP RLM, and with the ongoing work with SAP on further developments, will allow for better reporting and management going forward.

Returns

In nearly all cases of outbound logistics i.e. picking, packing, shipping to offshore platforms – there is a reverse element for inbound logistics i.e. shipping goods back onshore for some of the following reasons:

- Repair or refurbishment

- Scrap or waste

- Stock or return to vendor

When offshore platforms are decommissioned, projects are completed, excess materials are not required or items have been incorrectly ordered – they all have to be returned onshore for processing.

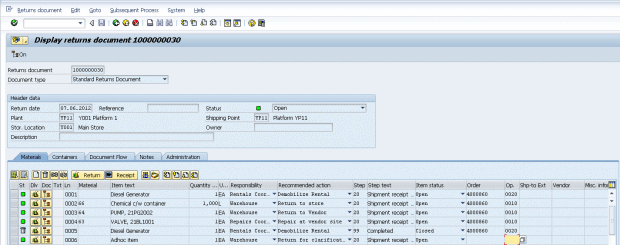

SAP RLM Return provides a Returns Document to help capture the items being returned but also where they are to be returned to and for what purpose (as above). This can be for either stock items, non-stock items or containers. The Returns document also gives you the functionality to help execute the subsequent documents required in the process i.e. transport order, shipping documentation.

Items can be added on an ongoing basis to the returns document and it is standard procedure to create one per return shipment. Once the subsequent delivery documents have been created, then the normal pick/ pack, shipment and transportation processes are executed this time only in reverse to that of the outbound process i.e. reverse shipping and receiving Plants and Storage Locations.

The details captured in the Returns Order will then form the basis for the shipping documentation i.e. the Manifest. In this you can capture individual information per material, text information per delivery and also certification or dangerous goods information maintained within your SAP system.

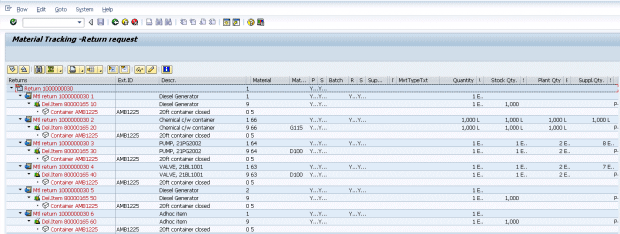

Once shipped from the offshore Plant and received at the onshore Plant, items can then be segregated and actioned as per the recommended action. For both onshore and offshore personnel, reporting of return items is handled via specific RLM Tracking reports which allows for the selection of returns document and a status where they are in the process flow.

Conclusion

SAP RLM for Rentals and Returns addresses unique aspects of the outbound and inbound logistics used offshore. Functionality allows for the separation of the rental equipment and the weekly/ monthly costs which are to be invoiced. Once no longer required or demobilised, SAP Returns allow for Rental items as well as other equipment’s, materials, containers to be returned onshore for the appropriate action, helping to utilise excess materials, items being decommissioned or no longer being in use.