ADIMA ERP for Manufacturing

Transform your business processes with a cloud ERP solution.

Is a limited software slowing down your business and limiting your growth? Working closely with UK SMEs to correctly identify pressing current and future needs, Absoft have built ADIMA so SMEs can unleash the full power of a world-class ERP without making a compromise on functionality.

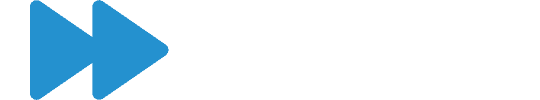

ADIMA provides one version of the truth in all key production processes – live, on mobile, tablet, laptop and desktop. See how you can increase productivity and efficiency, cut costs, introduce transparency across the whole business and improve sustainability – Book a DEMO to see ADIMA in action.

An industry-specific ERP

Absoft ADIMA ERP is an industry-specific, single, truly integrated, and intelligent system. Hosted on SAP S/4HANA cloud and based on the latest technologies, ADIMA’s database runs in-memory meaning that the reporting and analytics in the system are live allowing your business to identify, pre-empt, and improve sales, shop floor, and top floor.

Production

Logistics

Supply Chain

Assets & Inventory Management

Finance & Receipts Management

HR

Quality Management

Sales

Key Benefits

Fast Deployment

Implementing ADIMA can take as little as twelve weeks. Being a pre-packaged ERP, ADIMA will meet most of your process needs out of the box. We work with you to identify the needs specific to your business and tailor the system so that it is bespoke to you.

Shopfloor App

Full Visibility

The ability to truly see how the factory is performing helps you make clear critical decisions, prevent delays, drive change, improve quality of the service and discover problems you weren’t aware of.

Increased Security

Hosted on SAP S/4HANA Cloud, your data will be secure and safe. Any risk of data loss and breach will ultimately decrease.

Time-proof

Your ADIMA system will never become out-of-maintenance. Hosted on SAP S/4HANA Cloud, ADIMA will continuously grow and evolve with you and will adopt the latest technology, so you will never have to work with an outdated system again.

Download our customer success story

Why Absoft?

Absoft is a UK SAP Consultancy with 30 years of expertise in SAP implementation, optimisation, and support. Our experts have developed ADIMA, the SAP Partner-Packaged accredited solution, with SME manufacturers in mind to enable them to reach their business’ maximum potential.

Our team is dedicated to becoming an extension of your own team and learning about your business to ensure we can achieve the best results, together.

We pride ourselves in being transparent throughout your journey and making it as open and informative as possible.

We roadmap your ERP journey, ensuring relevant investment is made and walk with you on every step of the journey.